Forming a real company, creating a working prototype of a new multipurpose drone, making components from scratch, and getting electronics and software to work together is filled with seemingly unending difficulties.

Imagine doing all that as a high school student under the time constraints and pressure of being part of an international competition.

Now, figuring out how to succeed when surviving the coronavirus requires the four team members to mostly work remotely and, when together, remain social-distance safe.

This is the second installment of a multi-part interview series with tech-savvy teens who are entrepreneurs. See the first interview here.

Welcome to the world of four Naperville North High School students in a western suburb of Chicago. Their entrepreneurial and technical skills earned them the top award, Pete Conrad Scholar, for their product invention, Airlyft.

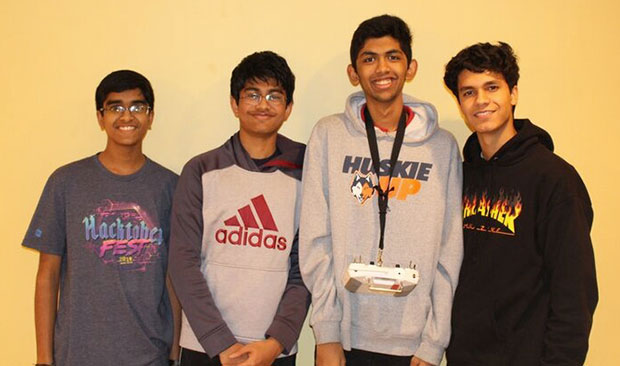

Arjun Shah, Aditya Dhingra, Jimit Gosar, and Nithilan Kalidoss have been working together closely since August 2019 to develop Airlyft. That is the name the four students chose for their versatile drone that uses tractable wings to fly faster and longer as part of The Conrad Challenge.

The Conrad Challenge is a multi-phase STEM (Science, Technology, Engineering, and Math) and entrepreneurship competition. It is so much more challenging than a science fair.

The students recorded a video presentation to pitch their business plan for Airlyft. This included market research, prototyping, and go-to-market plans. Then, they answered a series of questions from a panel of judges.

How It Worked

Prior to this competition project, each of the students had connected and participated in various projects together through the school district’s drone club and robotics team. After coming across The Conrad Challenge, the students decided to work together to submit their own drone project.

For the competition, they chose the name EcoAero to identify their team. Along the way, they formed a company of the same name, built a website for information, and planned an eventual marketing strategy for their product.

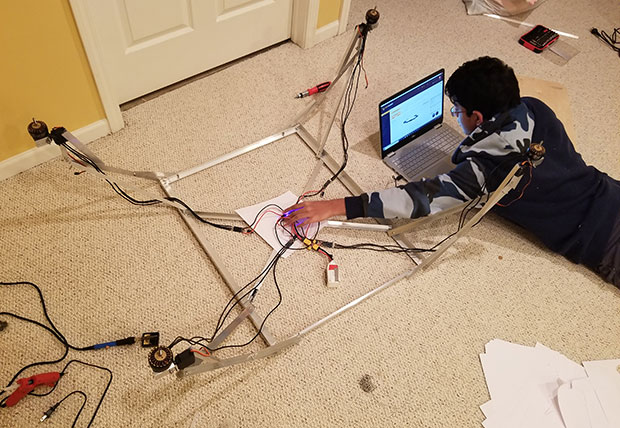

Team EcoAero took the invention a step further by building a prototype of the drone to demonstrate its cutting-edge retractable wings that help to ensure higher flight times and performance. As an effective solution to drone flight time issues, the students listed a variety of possibilities for its use, including firefighting, package delivery, seed-based agriculture, fertilizer-based agriculture, surveillance, sanitation, and electrical land inspection.

This year’s Challenge began in August 2019. Teams submitted their initial entry and worked on their investor pitch, which they completed in November.

Qualifying teams then advanced to the second round in mid-November and worked through mid-January to develop and refine a business plan, market study, and visual representation of their commercially viable solutions. Their products were then reviewed and scored by subject matter experts and judges before the finalist teams in each category were selected to present at the Innovation Summit.

The 2020 Virtual Innovation Summit, the final phase of the competition, took place from May 27-29 and included 37 international finalist teams who emerged from more than 600 teams that entered the Challenge in August 2019 from nine different countries.

At the Summit, team EcoAero shared their recorded power pitch to present their business plan for Airlyft, which included market research, prototyping, and go-to-market plans.

Team EcoAero was named Pete Conrad Scholars, the top award, at The Conrad Challenge Innovation Summit in the category of Aerospace & Aviation.

The Birth of Airlyft

The four students had been working independently in their spare time in the evenings and weekends. Their idea had evolved over the course of the year. They refined their ideas and incrementally made improvements, according to Jubin Gosar, faculty advisor and tech mentor.

Gosar, student Jimit’s father, was invited to be their coach and mentor in January 2020 after the boys were selected as one of the five finalists in the aerospace category. He is a mentor on the school’s robotics team.

“The prototype they built looks awesome. They felt really proud of the prototype and everything that they delivered for the Conrad Challenge,” Jubin Gosar told TechNewsWorld.

The team worked with perseverance, even late into the night, to be able to optimize the time and make the best of the situation, he added.

“They all have different career interests, but seeing them work together in spite of their different backgrounds makes me feel proud of them,” he said.

TechNewsWorld recently met with Team EcoAero on a video conference call to discuss how the students applied teamwork, persistence, and technology to overcome the constant setbacks imposed by COVID-19.

The first portion of our discussion is summarized as composite responses from all four students. The rest of the interview recounts the individual responses as the team members took turns answering questions.

TechNewsWorld: At what age did you begin to become actively involved with technology?

Team EcoAero: Most of us became very active with drone technology by our freshman year through school clubs and personal experience. We were all interested in mechanics and especially aviation as we wondered why certain objects were able to fly and how we could make them better.

TNW: What influenced you to get involved in the Conrad Challenge and the 2020 Virtual Innovation Summit?

Team: We are part of an aviation club at our school. We were getting only three-to-four minutes of flight times, and we realized that this problem must also plague the commercial drone market.

Arjun had previously participated in the Conrad Challenge, and we found that our idea was the perfect combination of the viability and innovation that the Conrad Challenge seeks to promote.

TNW: How has your experience at Naperville North High School expanded your interest and skills in technology?

Team: Naperville North provided us with the clubs and skills necessary to pursue our interests in engineering and aviation. Specifically, three of us were involved in Naperville North Robotics, through which we learned the process of designing, creating, and testing a product. We were also involved in a drone club called Flying Huskies, where we learned more about aviation and the electronics necessary for hobbyist drones.

TNW: What career goals do you have in your future?

Team: We all want to go into engineering. Arjun wants to focus on aviation. Aadi wants to go into finance and start a company. Nithilan and Jimit want to pursue computer science. Currently, we are continuing to develop our company, EcoAero, to do our part in making commercial drones viable.

Aadi Dhingra: I plan to go to the Michigan Ross School of Business next year. I will take my resources from there and use them to help our company. There will be fascinating networking opportunities and tons of entrepreneurship competitions available to high school and college students. So, I will direct all of my financial resources to help grow our company.

TNW: How difficult has it been working as a team yet having to remain under social distancing for much of the time?

Arjun Shah: COVID-19 really changed how we had to work together. We had a weekly sheet of everything that had to get done. We were planning about four-to-six weeks out. We made numerous video calls each day and focused on what needed to be completed, and kept track of which ones we hadn’t started.

One major problem was actual hands-on productivity. We could only have one person working on the prototype at one time. I had all of the parts at my house, but I didn’t have as much experience as the other guys. So sometimes we would be on a video call for two or three hours with them just watching what I was doing and commenting to help me out. It was definitely an interesting experience.

TNW: You obviously know each other well. What did you learn about the dynamics of working together?

Aadi Dhingra: We did a good job of assigning roles. Right off the bat, we already knew who would do what tasks. Arjun Shah – CEO; Aditya Dhingra – CFO; Jimit Gosar – CTO; Nithilan Kalidoss – CIO.

That was very helpful. We could assign tasks to the person who specializes in that area. However, it was difficult to have to guide each other through video calls and have all of our discussions online.

Jimit Gosar: We also have very diverse experiences.

Nithilan Kalidoss: My expertise was in software since I am the CIO. For example, I made a website where people could go to submit orders and view information about the drone project.

TNW: How did you handle the parts acquisitions? Were you able to 3D print what you needed?

Arjun Shah: We made all the parts from scratch. We used off-the-shelf electronics and got aluminum from Home Depot. We designed most of our parts using CAD software. I’d send them over to Jimit for printing, and he’d send them back to me for assembly and testing.

TNW: Are you actually selling products yet?

Arjun Shah: Not yet. We have a website, but it is more for a demonstration. We are still in product development right now. Once we finish that, we hope to start selling to customers.

TNW: So you are inventing things to solve problems. Have you patented your inventions to prevent people from stealing the rights to them?

Jimit Gosar: Absolutely. One of the requirements of the Conrad Challenge was to file a patent. So we talked to experts about that and then filed a provisional patent to protect our ideas.

TNW: What about the money issues? Did your school kick in money to cover your operating expenses, or is that coming from your own pockets, family, and friends?

Nithilan Kalidoss: We started with our own pocket money. For future expenses, we plan on collecting from friends and family. For now, to cover the entry costs of the competition, we all pooled about $400 or $500 each to cover the $3,000 to create our product.

TNW: What roadblocks have the team faced?

Nithilan Kalidoss: The coronavirus was definitely a big obstacle for us. It prevented us from working physically together. For the third round of the competition, we had to submit an eight-minute video pitch. Since sending large files over the network is really slow, we had to restrict one person to do all of the video editing instead of splitting it up more.

Arjun Shah: Prototyping was another difficulty we had to solve. Social distancing kept us from being together for much of that work. I am not as skilled with that, but since all of the pieces were at my house, I had to follow through. I had very little experience with the type of electronics we used.

We had to have two or three video calls, sometimes for three hours during the day. Jimit and Nithilan would walk me through some very basic electronic stuff. That was definitely the most complicated thing to tackle.

I had to solder and re-solder many, many times. Even the software was very difficult for me to use. I had to figure out how to assign controllers on the transmitters to certain motors. There were so many moving parts, and it was a somewhat unconventional drone. Electronics and software were definitely a big roadblock.

Because I was able to get their help through video calls, we were able to solve it by working together while still apart.

TNW: How did the software issue get solved? Did you have to write your own code or use something else?

Arjun Shah: Because we were using off-the-shelf electronics, we were able to use open-source software. That was very helpful.

Jimit Gosar: In the future, we plan to use a more advanced flight controller. That will make it easier to add additional rotating mechanisms. We used open-source software that works well with drones and mission programming.

TNW: What’s involved in making drones more commercially viable?

Arjun Shah: Right now, one of the biggest problems facing the viability of commercial drones is their flight time. You can’t do much with a drone that has only 30 minutes of flight time and barely 10 kilometers of range. So, what we are doing here is increasing the flight time and the range of drones.

Most of our competitors use quad-copters. They basically have four propellers facing up. You take off vertically and tell it to move in any direction and land vertically. They chose that because of its versatility. You have hovering capability and speed control for a given payload. But quad-copters take up a lot of power so you don’t have a lot of flight time.

We wanted to find a way to convert the versatility of a quad-copter and a winged drone to give it longer flying time. It is significantly longer. What we did essentially is combine the characteristics of a winged drone and a quad-copter. We created a drone that can horizontally take off and land has a horizontal flying component that can go in any direction because its motors tilt like an airplane, and its wings retract to handle speed control and still fly at whatever speed you want.

So what we are doing is making drones with the flight times of winged drones and the versatility of quad-copters. What that does is create a product that can be used for a variety of different things.

We made a base model and a series of modules that can be interchanged for different tasks. We have firefighting modules, package delivery modules, and even a sanitation module that we developed due to COVID-19. This makes a very practical drone that can be used for anything.

Do You Know a Tech-Savvy Student?

Do you know a tech-savvy student you’d like to suggest for a TechNewsWorld feature? Are you a student who’s ready to leap into the spotlight yourself?

Please email me, and I’ll consider scheduling an interview.

And use the Reader Comments feature below to provide your input!